It’s been nearly three years since the UK voted to leave the European Union. Since then, a number of big multinationals have been planning for Brexit, with some —like Dyson, Nissan and Sony—choosing to move their European or global company headquarters overseas.

For smaller firms, the lack of clarity about the post-Brexit environment means many are adopting a ‘wait-and-see’ strategy. Others, however, are proactively investing in technologies that will give their business the agility required to cope with fast-evolving market scenarios.

There are some very specific challenges being banded around, so here we will aim to tackle some of the topics most discussed in relation to Brexit and manufacturing, and look at some of the steps that can be taken to mitigate their impact.

Falling labour resources

As the flow of European workers slows ahead of Brexit, forward-thinking manufacturers are investing in automation and robotics as workers become more scarce and costly. Automating labour-intensive processes could generate major benefits for UK productivity, which currently lags more than 20 percent behind the US, France and Germany.

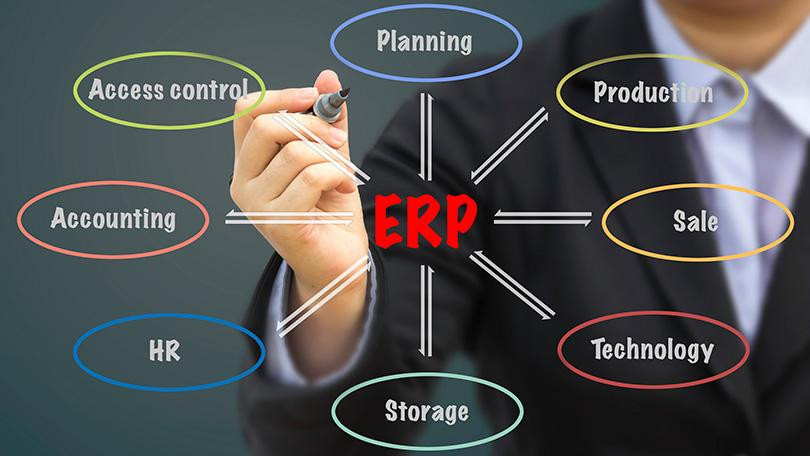

Modern enterprise resource planning (ERP) solutions will be crucial to coordinating robot workflows and enabling the sharing of data between machines and humans across multiple digital platforms. This, along with the addition of increased data processing efficiencies, and valuable real-time and data-driven insights, will allow manufacturers to navigate the murky Brexit waters, improve productivity and more easily drive future business growth.

Capturing data from production lines can also be used to undertake real-time monitoring of all activities, enhance process flows, and enable a more connected supply chain.

Supply chain disruption

Cross-channel goods could be reduced by 87 percent post-Brexit—which means the supply of components and raw materials manufacturers rely upon could be severely limited. Torn between planning for border gridlock caused by a no-deal Brexit, many manufacturers are said to be turning to stockpiling.

As a result, UK warehouse space is nearing capacity, as manufacturers revert from ‘just-in-time’ (JIT) production models to ‘just-in-case’ models, in which high precautionary inventory levels are maintained.

While such contingency planning may help counteract potential supply chain disruptions on the horizon, it also increases the risk of waste or obsolescence—putting extra strain on already pressured firms.

Here, investment in supply chain management (SCM) software could help manufacturing companies to identify added-value activities, reduce and eliminate non-value-added activities, and move back towards a leaner and more efficient supply chain.

Made in Britain

The UK is synonymous with low-volume, high-quality, and high-value products. With trade tariffs predicted to squeeze margins, many UK manufacturers are looking to re-focus on near-shoring ‘Made in Britain’ manufacturing opportunities.

There are a number of reasons for bringing operations back to the UK or closer to home—rising overseas labour costs, modern slavery issues, maintaining control over operations and processes, and the positive brand benefits resulting from bringing jobs ‘home’.

Managing the supply chain for a changing world means management will need to have deep insights into how supply chain costs could change over the next five years while building up a new and trusted UK supplier base. Today’s modern ERP can make it easy to rebalance inventories and supply chains and make more informed decisions in real time.

The only certainty is, there will be more uncertainty

In these unpredictable times, modern ERP systems can enable manufacturers to respond to changes within the supply chain, adapt easily to new business models, and gain data-driven insights that inform decision-making and strategy.

By Mark Hughes, Regional Vice President UK & Ireland, Epicor