Sustainable logistics are tied to strategies that are meant to increase the sustainability of operations throughout the whole supply chain. This approach covers everything from raw material supply through processes of transformation, storing, packing, as well as shipping. The main goal of these logistics is to improve the economic and social sustainability of a company’s logistical operations. However, that doesn’t mean that lowering the environmental footprint is unimportant. The goal is also to minimize the negative externalities associated with business operations for the environment, the economy, and society as a whole. Because of the transformation from a linear economic model to a more circular industrial model, these logistics have become extremely important. For this reason, we have decided to discuss these logistics and why they matter.

What Exactly Is Sustainable Logistics?

The supply chain is one of the essential aspects you need to get right if you want your business to succeed. If you have a strong and controlled supply chain, you won’t have any issues getting your products to your customers or distributors. Sustainable logistics also aims to make all aspects of your supply chain green without compromising your bottom line. If you implement them into your system, you will lower the CO2 emissions that your operations produce. You will also lower the noise pollution.

However, the goal will also be to increase the safety of your logistics workers. If you use this method, you can take a comprehensive look at all aspects of your company’s logistics. Once you do this, you can run a much more effective business. According to experts from beltwaymovers.com, some of the elements of your logistics operation that can influence sustainability are:

- The routes that you use for deliveries.

- Where and how you store your inventory.

- The type of transportation that you mainly use.

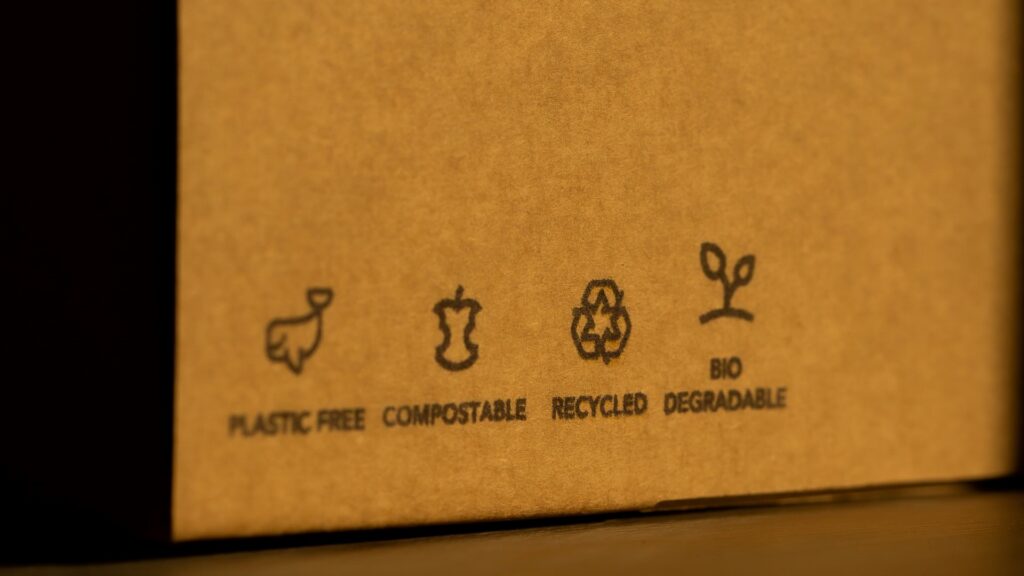

- Materials that you use for packing.

The Advantages Of Long-Term Sustainable Logistics

There are many advantages to implementing these logistics. As we’ve mentioned earlier, you will leave a much smaller footprint. However, this is not the only advantage. They can also increase the overall effectiveness of your business. For example, it will compel you to plan ahead of time and identify the most viable solutions to your problems. If you use a fleet of vehicles for shipping, sustainable logistics will help you streamline the entire process. This will ensure that you are doing things in the most efficient manner possible.

This is also an excellent strategy if you wish to earn respect and trust of many new prospective customers and partners. When you implement a logistics plan for your company, you show your customers that you are making significant efforts to improve your business, even in the face of many other challenges that are ahead of you. This will also show them that you don’t want to fall behind in the industry. Logistic methods will also enable you to compete with industry leaders in your field. As a result, if you’re looking for a measurable way to modernize or improve your company, look no further than sustainable logistics.

How To Implement These Logistics

Now that we have discussed what these logistics are and how you can benefit, we will cover what you must do to implement this method correctly.

1. Measure Your Baseline

The first thing you should do is figure out where you are right now. You must assess the efficiency of your entire process. The process should start with defining the main criteria. This includes everything from raw material and energy consumption to the fuel required to complete your process. Once you’ve done that, you’ll be able to calculate your carbon footprint. The second phase involves evaluating the impact of various processes in the supply, manufacturing, and distribution cycles. If you do this, you can determine your priorities and goals successfully. However, you must clearly understand all of your responsibilities to do this properly.

2. Define All Of Your Goals

As previously stated, once your measurements are complete, you can begin to define your goals. You need to know exactly what you want to accomplish to do this. Once you have determined that, you must determine how complex these goals are and then organize them accordingly. The level of complexity refers to how much effort you will need to put in to achieve the desired result. If you know how much work will be involved, you can allocate your budget better to specific goals. Once you have determined your goals, you will also be able to decide the level of urgency between the different goals.

3. Make A Plan Of Action

After you’ve defined and organized all of your goals based on the amount of work required and the urgency, you can begin developing a plan of action. This plan will include all the steps and work you will need to complete to achieve your objectives. A successful action plan includes comprehensive and quantifiable goals, as well as a roadmap with major milestones. A good plan also includes a timetable, opportunities to assess progress, organizational responsibilities, and performance indicators. If you have all of these metrics, your project managers can evaluate your efforts’ effectiveness.

4. Evaluate And Iterate

Now that you’ve devised a strategy, all that remains is to put it into action. However, once you’ve done that, you can’t just walk away and hope for the best. You must monitor how well your strategy is working. You’ll be able to spot flaws or irregularities in your plan if you keep an eye on how things are going. This allows you to iterate, tweak, and improve your process as you go.

Conclusion

Sustainability is the future for logistics and supply chain businesses. It is important to understand the level of social, environmental, and economic impact and viability that suppliers and customers have. It is beyond going green and being environmentally friendly. Sustainable logistics influences manufacturing processes as well. For this reason, it is essential to know what it is and why it matters.